Device description

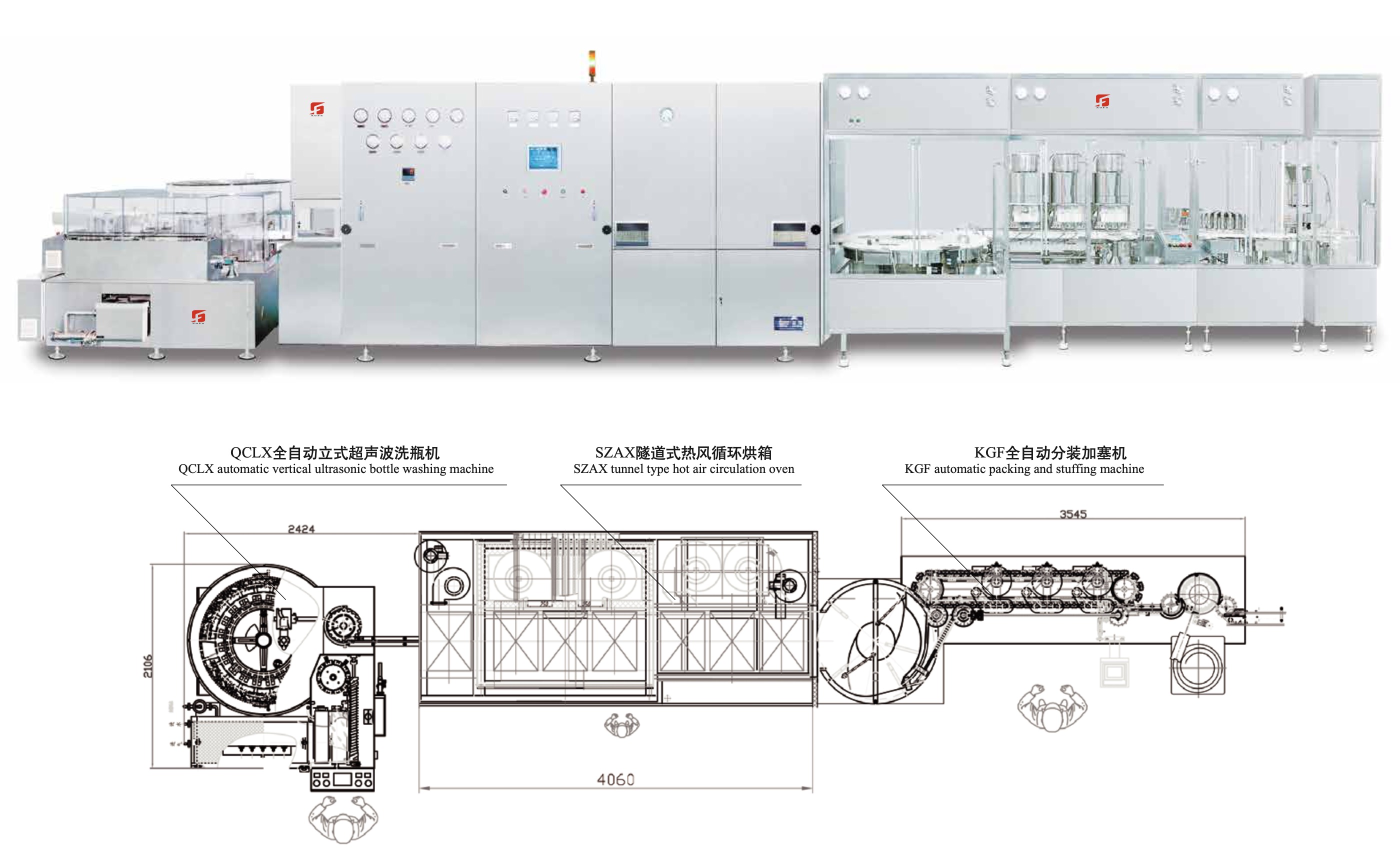

Fully automatic washing, drying, packaging and stuffing production linkage line is a high-quality and high-output linkage line designed for powder packaging production in accordance with GMP standard. It is composed of QCLX series vertical ultrasonic bottle washing machine, SZAX series hot air circulation tunnel sterilization oven and KGF packaging unit. Ultrasonic bottle washing machine can complete the ultrasonic rough cleaning of the bottle, the bottle wall cleaning, three gas three water cleaning inside the bottle, hot air circulation tunnel sterilization oven can clean the bottle for drying, sterilization to heat source, KGF installer adopts multi-head intermittent packaging, directly into the bottle after the packaging material stuffing, no secondary pollution. This linkage line is equipped with foreign instruments, which can test, print and store process parameters online. At the same time, the filling and filling machine is equipped with an isolation protection system, in line with the new version of GMP, CGMP requirements.

Features of equipment

The equipment is stable in operation, advanced in configuration, complete in function, beautiful in appearance, safe and reliable, and highly intelligent.

Range of application: 2-25ml, 100-400 bottles/min. The equipment can display, print and store the process parameters, operation status and other important data online. The real-time monitoring equipment is equipped with automatic shutdown and alarm function. The bottle washing machine has the function of ultrasonic cleaning and adopts the tracking cleaning system to clean the inner and outer walls of bottles one by one to ensure the quality of bottle washing. The circulating water of bottle washing machine can be used as ultrasonic spray water and pre-cleaning to save water.

The heat distribution of sterilization oven is even and the heat utilization rate is high. The cooling section of sterilization oven can be air-cooled or water-cooled, and can be sterilized online. The machine adopts multi-head batch packaging to directly pack sterile raw materials into bottles to avoid secondary pollution. The dividing machine can complete production under isolation protection, and the environmental index of the dividing area can be detected at the same time. Provide complete verification documents to assist GMP and CGMP validation.